Digital Denture

Say Goodbye to Tedious Denture Appointments — Hello to Precision in 2 Visits

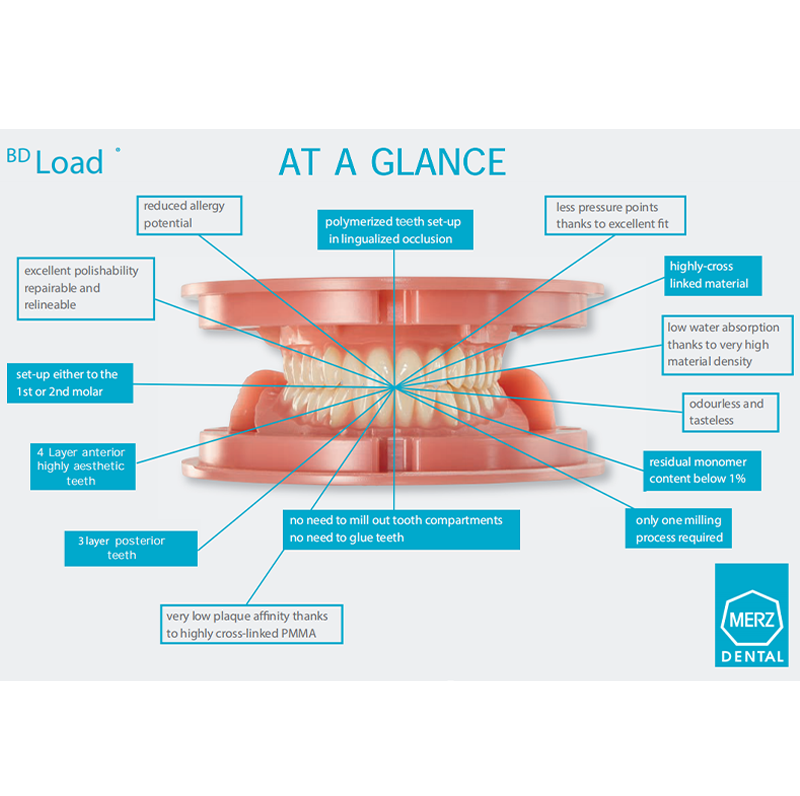

Tired of endless adjustments and patient complaints? Discover the BDS digital denture system — crafted with German quality, real multilayered denture teeth, Merz acrylic, delivered fast, and guaranteed to fit.

Digital Dentures

The Traditional Denture Process is Outdated

Multiple appointments. Frustrated patients. Time-consuming adjustments. Dentures that just don’t fit right. This is the reality for many clinicians still relying on conventional methods.